Stainless Steel 904L is a tremendous austenitic stainless steel alloy noted for its great corrosion resistance, immoderate electricity, and extraordinary weldability. It is often applied in numerous commercial enterprise applications in which resistance to competitive environments is crucial. In this blog, we can discover the composition, homes, and uses of Stainless Steel 904L flanges, with a focus on its software in buttweld fittings.

Composition of Stainless Steel 904L

Stainless Steel 904L is a low carbon, excessive alloy austenitic stainless-steel grade with additions of nickel, chromium, and molybdenum. The composition of Stainless Steel 904L usually consists of:

- – Carbon (C): Maximum 0.02%

- – Silicon (Si): Maximum 1.Zero%

- – Manganese (Mn): Maximum 2.0%

- – Phosphorus (P): Maximum zero.Half%

- – Sulfur (S): Maximum 0.Half%

- – Chromium (Cr): 19.Zero% – 23.Zero%

- – Nickel (Ni): 23.Zero% – 28.Zero%

- – Molybdenum (Mo): 4.Zero% – five.0%

Properties of Stainless Steel 904L

- Corrosion Resistance:

Stainless Steel 904L is well-known for its incredible resistance to each lowering and oxidizing acids, making it appropriate for applications in aggressive environments which include sulfuric acid, phosphoric acid, and chloride solutions. It moreover gives appropriate resistance to crevice corrosion and strain corrosion cracking.

- High Strength:

Stainless Steel 904L has immoderate tensile and yields electricity, permitting it to face up to excessive strain and excessive temperature conditions without gift technique deformation or failure. Its superior mechanical holmes make it perfect to be used in worrying industrial programs.

- Weldability:

Stainless Steel 904L offers extremely good weldability and can result easily welded with the usage of conventional welding strategies inclusive of TIG (Tungsten Inert Gas) welding, MIG (Metal Inert Gas) welding, and SMAW (Shielded Metal Arc Welding). The alloy continues its corrosion resistance and mechanical homes after welding, making it appropriate for fabrication.

- Heat Resistance:

Stainless Steel 904L is a famous suitable resistance to oxidation and scaling at extended temperatures, making it appropriate to be used in packages involving warmness publicity, which encompass warm temperature exchangers, furnace components, and annealing devices.

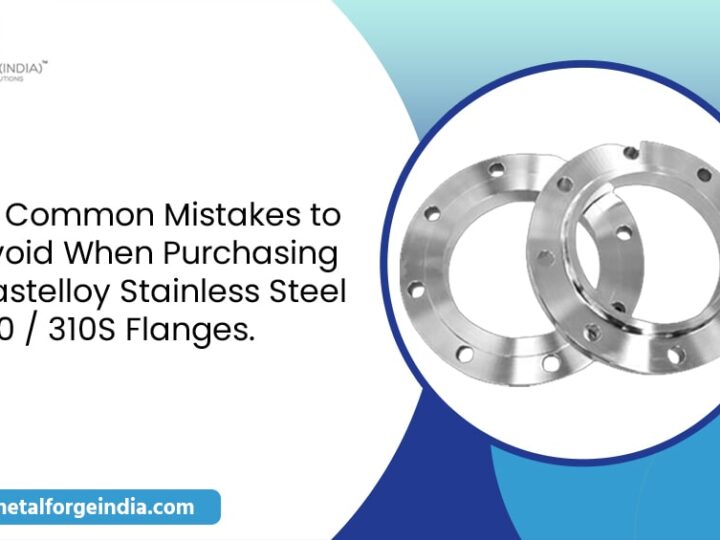

Uses of Stainless Steel 904L Flanges

Stainless Steel 904L flanges are widely implemented in several industries for connecting pipes, valves, and gadgets in piping systems. Some common applications of Stainless Steel 904L flanges embody:

- Chemical Processing:

Stainless Steel 904L flanges are substantially applied in chemical processing vegetation for connecting pipelines, reactors, and vessels handling corrosive chemical substances and acids. Their superior corrosion resistance and mechanical power make them best for withstanding harsh chemical environments.

- Oil and Gas Industry:

In the oil and gasoline agency, Stainless Steel 904L flanges are implemented in offshore systems, refineries, and petrochemical plant life for connecting pipelines, valves, and systems uncovered to corrosive fluids, seawater, and excessive-pressure situations.

- Water Treatment:

Stainless Steel 904L flanges find packages in water remedy centers for connecting piping structures, pumps, and filters applied in desalination flowers, wastewater treatment flowers, and water distribution networks. Their resistance to corrosion and abrasion makes them suitable for handling corrosive and abrasive fluids.

- Chemical Industry:

Stainless Steel 904L flanges are utilized in pharmaceutical production facilities for connecting pipeline devices, reactors, and storage tanks. Their hygienic houses, corrosion resistance, and compatibility with sterilization techniques make them appropriate for pharmaceutical applications.

- Food and Beverage Industry:

Stainless Steel 904L flanges are employed within the food and beverage enterprise for connecting pipelines, storage tanks, and processing systems. Their non-poisonous nature, hygienic houses, and corrosion resistance make them suitable for dealing with food-grade merchandise and sanitization strategies.

Conclusion

Stainless Steel 904L flanges are important additives in diverse organization programs wherein corrosion resistance, strength, and reliability are paramount. Their flexible homes motivate them to be vital in chemical processing, oil and gas, water treatment, pharmaceutical, and food and beverage industries, contributing to the inexperienced and constant operation of enterprise strategies.